Products

New & Featured Products

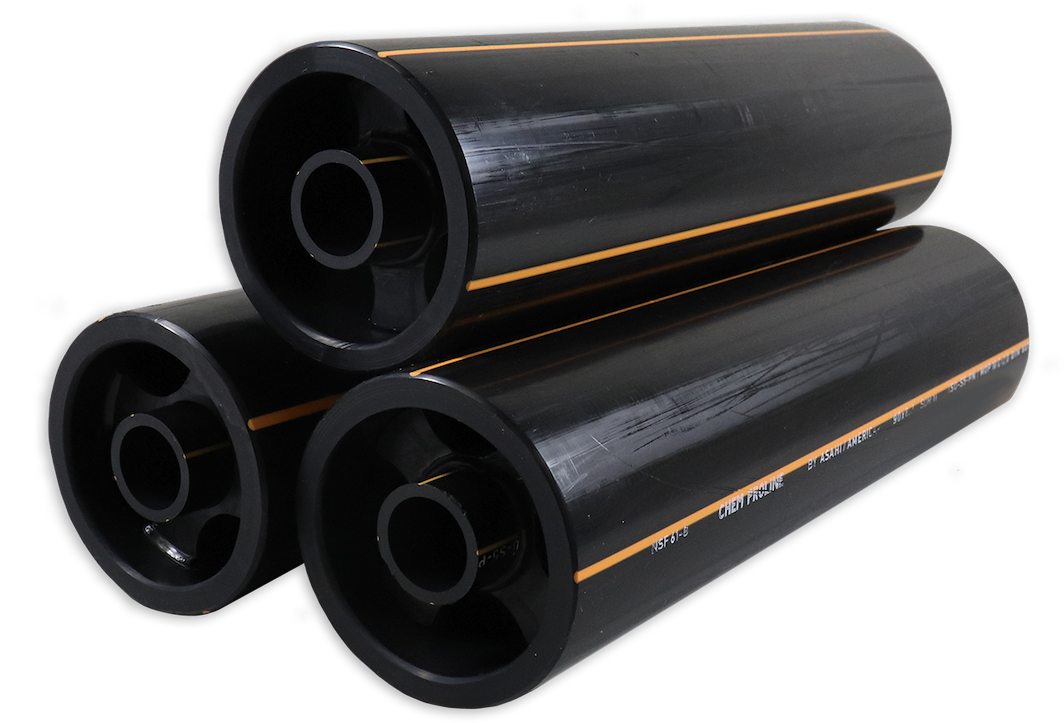

Chem Proline

Chem Proline® is composed of the latest evolution in Advanced Polyethylene (PE) resin technology. This new advanced PE material possesses excellent physical and mechanical properties. These properties include: stress crack resistance, slow crack growth resistance, ductility, impact resistance, abrasion resistance and brittleness resistance. Now available in 40″ – 98″ size as well!

Capable of handling some of the harshest chemical applications with a long-term expected useful life, Chem Proline® offers a greater value over metal, FRP, lined steel, or other thermoplastic piping systems like PVC and CPVC. Chem Proline®’s superior properties make it the only Polyolefin material able to handle certain chlorinated services like sodium hypochlorite. UV resistant, light weight, proven fusion joining technology, Chem Proline® is perfect for most chemicals found in the water treatment process.

Chem Prolok® Advanced PE

Chem Prolok® is a custom fabricated containment piping system that is ideal for sodium hypochlorite applications. Fabricated from our Chem Proline® crack resistant polyethylene, it is a cost effective piping solution for sodium hypochlorite, sulfuric, and hydrochloric applications.

Air-Pro® Compressed Air Piping System

Air-Pro® is the only PE piping system approved for use and warranted by the manufacturer for compressed air applications. Air-Pro® meets CAL-OSHA requirements for compressed air.

Air-Pro's® specially formulated PE resins are resistant to both synthetic and mineral compressor oils.

- Available in sizes ½” to 12” with socket, butt and electrofusion fittings in a variety of styles including tees, reducing tees, 90s and 45s

- Fast, low-cost installations

- Operating pressures from 150 - 230psi

- Constructed from specially engineered PE100/PE100RC uniform pipe and fitting materials which is extremely ductile, lightweight and corrosion resistant. The PE100 is high density polyethylene with a minimum cell classification of: PE445574E

- Chemically resistant to compressor synthetic oils and mineral oils that traditionally attack glued and metal systems

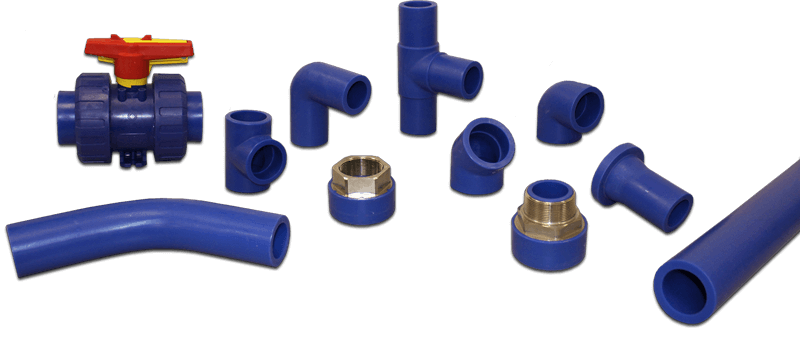

Type-21a SST Flow Control Valve

Introducing the Type-21a Seat Support Technology (SST) flow control ball valve which offers all of the robust elements of the Type-21 ball valve and the ability to precisely control flow.

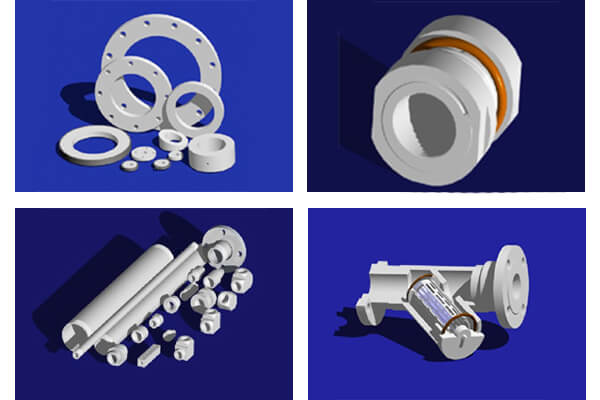

Since 1950, Micromold Products has manufactured a broad line of corrosion resistant plastic products for the process industries. Micromold specializes in standard and custom products made from PTFE, PFA, & FEP and such other high performance plastics as Kynar, polypropylene, PEEK, nylon, Kel-F, and UHMW polyethylene.